Mobility with Performance of Stationary Plant

The most striking feature of KYB-Conmat Batching Plant is faster & easy erection / dismantling at site. It has all welded frame structure & comes fully assembled from the factory in three parts. It can be installed at the site with an ordinary “Pick & Carry” crane available locally. Requires only few hours for installation.

A Low Maintenance Plant

Engineered to perfection, KYB-Conmat Batching Plant requires minimum maintenance, thus assuring continuous performance. We have invested heavily in state-of-the-art designing & manufacturing techniques to make the equipment, which is not only efficient but also perform in tough conditions.

Compact Overall Size

Sleek designed KYB-Conmat Batching Plant requires very less installation area & minimum civil works and hence good saving for the customers.

Controls

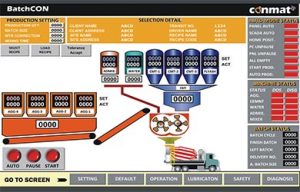

Intelligent PLC based Automatic Controls with SCADA.

Salient Features

-

- Fast & homogeneous mixing through world’s latest TWIN SHAFT MIXER technology

- Rugged and compact design of Mixer makes it suitable for all concrete applications

- Mobility with performance of stationary plant

- Requires minimum maintenance thus assuring continuous performance in tough conditions

- Higher accuracy because of higher capacity and more no. of load cells

- Minimum installation area & minimum civil work

- Committed towards confirmed concrete output

- Fully automatic PLC control system with SCADA for inventory management and different report generation

- Fault and errors diagnosis system

|

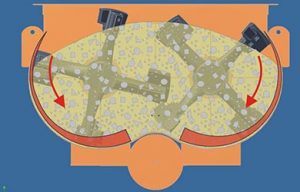

Long Wear Life Inherent Design of the mixer reduces wear of the tiles as compared to Pan and Planetary mixers, as only 30% of the tiles are subjected to wear. High quality of wear tiles ensures even longer life. |

|

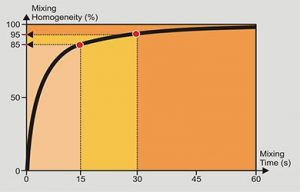

Fast Mixing 85% of the maximum mix quality i.e high compressive strength, constant slump etc. is achieved after only 15 sec. and after another 15 sec., 95% homogeneity is achieved. |

|

Better Mixing Quality All the particles achieve a three dimensional motion, thanks to intelligent placement of the mixing arms that creates a high degree of turbulence in the mixture. |

|

Deep Bucket Conveyor Makes Plant compact & has low maintenance. |

|

Advanced Control System Fully automatic PLC control system with SCADA for inventory management and different report generation. Any types of faults and errors will be diagnosed by the control system. |

|

Chevron Belt Conveyor Low replacement cost |

| No. | Details | CRP 250 IL |

| 1 | Output Theoretical | 25 cu. mtr./hr |

| 2 | In Line Bin | 3 / 4 |

| 3 | Charging Conveyor | Chevron Belt Conveyor |

| 4 | Cement / Filler Weighing System | Yes |

| 5 | Water Weighing System | Yes |

| 6 | Admixture Weighing System | Optional |

| 7 | Mixer | Twin Shaft |

| 8 | Maximum Size of Aggregate | 40 mm |

| 9 | Water Sprinkling & Gravity Discharge System | Yes |

| 10 | Air Compressor | Yes |

| 11 | Screw Conveyor for Cement | Yes |

| 12 | Cement Filling Hopper | Yes |

| 13 | Control System | Automatic |

| 14 | Discharge Height | 4.1 mtr. |

| No. | Details | CRP 300 IL |

| 1 | Output Theoretical | 30 cu. mtr./hr |

| 2 | In Line Bin | 3 / 4 |

| 3 | Charging Conveyor | Chevron Belt Conveyor |

| 4 | Cement / Filler Weighing System | Yes |

| 5 | Water Weighing System | Yes |

| 6 | Admixture Weighing System | Yes |

| 7 | Mixer | Twin Shaft |

| 8 | Maximum Size of Aggregate | 40 mm |

| 9 | Water Sprinkling & Gravity Discharge System | Yes |

| 10 | Air Compressor | Yes |

| 11 | Screw Conveyor for Cement | Yes |

| 12 | Cement Filling Hopper | Yes |

| 13 | Control System | Automatic |

| 14 | Discharge Height | 4.1 mtr. |

| No. | Details | CRP 450 IL |

| 1 | Output Theoretical | 45 cu. mtr./hr |

| 2 | In Line Bin | 4 / 5 |

| 3 | Charging Conveyor | Chevron Belt Conveyor |

| 4 | Cement / Filler Weighing System | Yes |

| 5 | Water Weighing System | Yes |

| 6 | Admixture Weighing System | Yes |

| 7 | Mixer | Twin Shaft |

| 8 | Maximum Size of Aggregate | 60 mm |

| 9 | Water Sprinkling & Gravity Discharge System | Yes |

| 10 | Air Compressor | Yes |

| 11 | Screw Conveyor for Cement | Yes |

| 12 | Cement Filling Hopper | Yes |

| 13 | Control System | Automatic |

| 14 | Discharge Height | 4.1 mtr. |

| No. | Details | CRP 600 |

| 1 | Output Theoretical | 60 cu. mtr./hr |

| 2 | In Line Bin | 4 / 5 |

| 3 | Charging Conveyor | Chevron Belt Conveyor |

| 4 | Cement / Filler Weighing System | Yes |

| 5 | Water Weighing System | Yes |

| 6 | Admixture Weighing System | Yes |

| 7 | Mixer | Twin Shaft |

| 8 | Maximum Size of Aggregate | 80 mm |

| 9 | Water Sprinkling & Gravity Discharge System | Yes |

| 10 | Air Compressor | Yes |

| 11 | Screw Conveyor for Cement | Yes |

| 12 | Cement Filling Hopper | - |

| 13 | Control System | Automatic |

| 14 | Discharge Height | 4.1 mtr. |

| No. | Details | CRP 750 IL |

| 1 | Output Theoretical | 75 cu. mtr./hr |

| 2 | In Line Bin | 4 / 5 |

| 3 | Charging Conveyor | Chevron Belt Conveyor |

| 4 | Cement / Filler Weighing System | Yes |

| 5 | Water Weighing System | Yes |

| 6 | Admixture Weighing System | Yes |

| 7 | Mixer | Twin Shaft |

| 8 | Maximum Size of Aggregate | 80 mm |

| 9 | Water Sprinkling & Gravity Discharge System | Yes |

| 10 | Air Compressor | Yes |

| 11 | Screw Conveyor for Cement | Yes |

| 12 | Cement Filling Hopper | - |

| 13 | Control System | Automatic |

| 14 | Discharge Height | 4.1 mtr. |